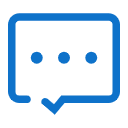

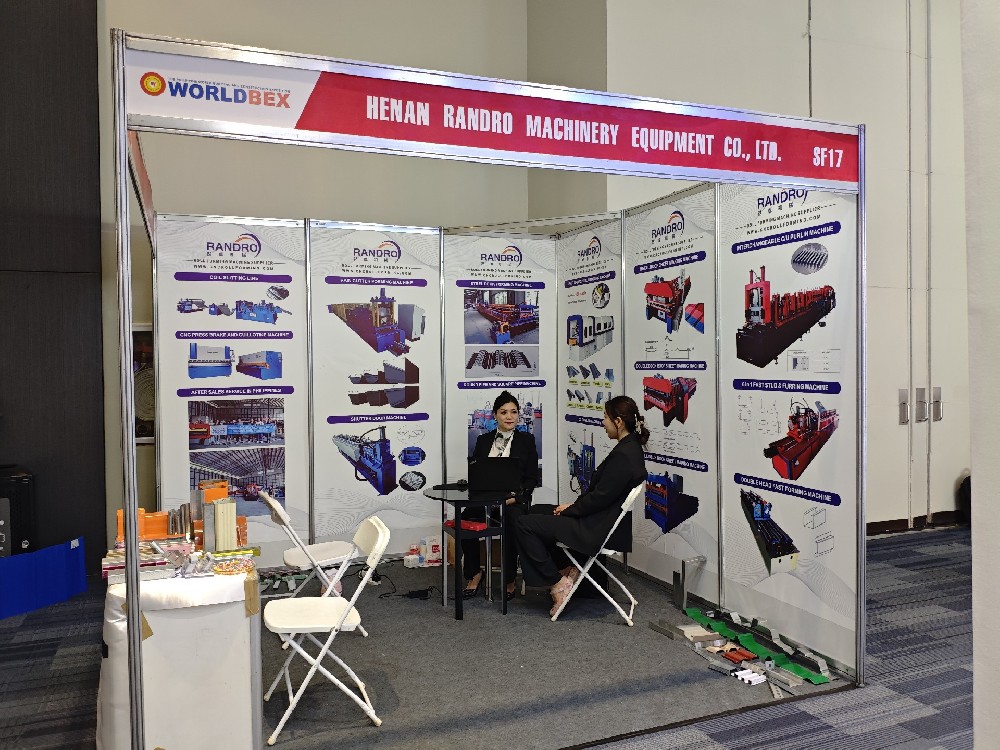

In modern industrial production, cable tray roll forming machines are widely welcomed by the market due to their high efficiency and high degree of automation. Recently, two batches of Kazakhstani customers visited our cable tray roll forming machine factory to learn about the operation and production process of these machines.

|  |

Cable trays are an indispensable component of modern architecture. They not only protect cables, but also facilitate cable routing and maintenance. Before visiting, we first understand the customer's needs for cable trays. Subsequently, the customers were guided to the production line and witnessed firsthand the operation of the cable tray roll forming machine.

|  |

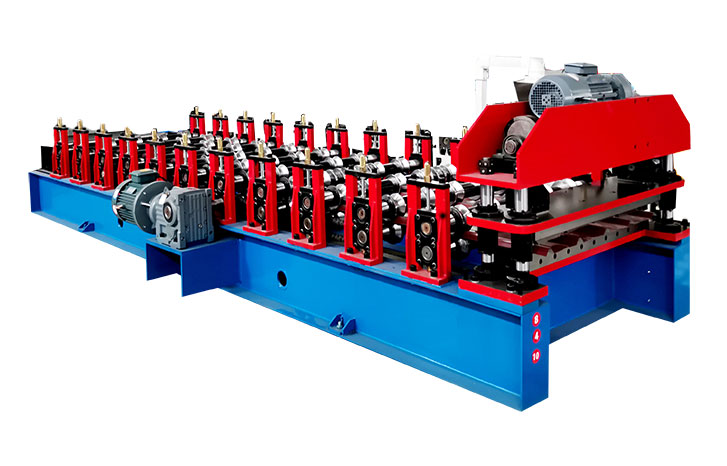

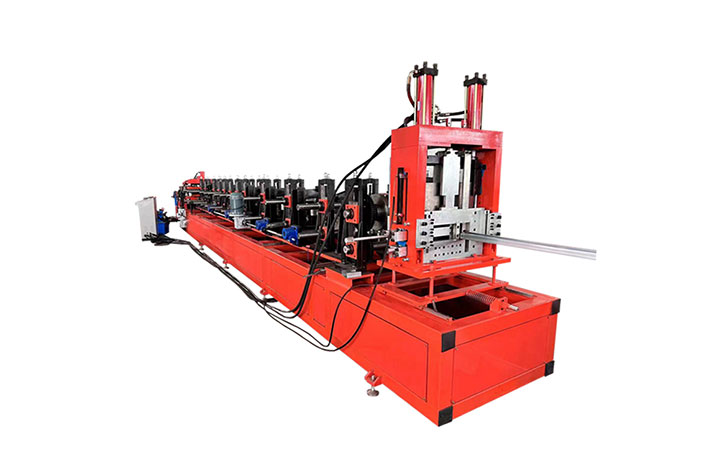

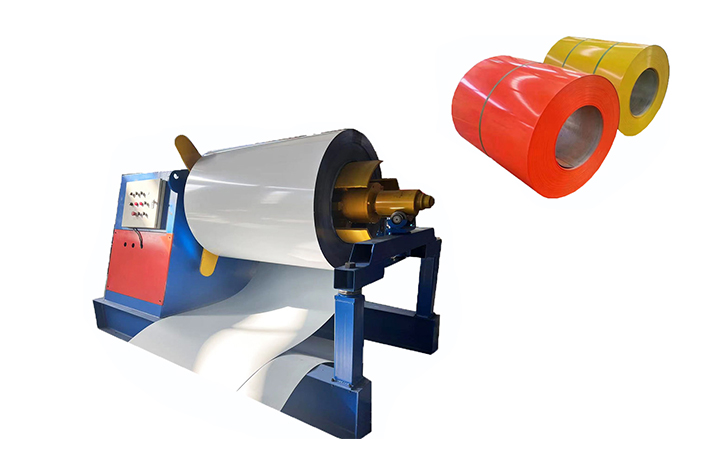

On the production line, precision machines are working efficiently. The entire process from unwinding, leveling, pre punching, roll forming to final fixed length cutting is almost completely automated, requiring only a few operators to monitor and adjust. Customers expressed admiration for the high efficiency and stability of the machine. According to the factory technicians, these machines can be customized according to customer needs to adapt to the production of different specifications of cable trays, ranging from 100mm to 800mm, and the thickness can be from 0.6mm to 2.0mm.

|  |

During the visit, the customers paid special attention to the ease of machine operation and the precision of the finished product. The technicians explained that the cable tray roll forming machine adopts an advanced automatic control system, which can accurately control the operation of each link, ensuring the consistency and accuracy of product dimensions. In addition, the molding machine uses high-quality raw materials and ensures the strength and stability of the product through high-temperature heat treatment and surface treatment.Customers have also expressed interest in the energy-saving and environmentally friendly features of the machine. The factory manager pointed out that these machines are well-designed, reasonably priced, easy to operate, stable, and have a high yield rate, making them an ideal choice for cable tray production enterprises.

|  |

Finally, the clients visited the finished product area, where various specifications of cable tray samples were displayed. They are satisfied with the quality and diversity of the products and are looking forward to future cooperation.

|  |

In summary, this factory visit not only gave customers a deeper understanding of the cable tray roll forming machine, but also enhanced their confidence in the factory's production capacity. With the continuous development of automation technology, cable tray roll forming machines will undoubtedly become the mainstream production method in the cable tray industry.

2024-09-24 11:28:23

2024-09-24 11:28:23

Contact us for detail

Contact us for detail