Are you still worried about how to choose a CZ roll forming machine? Are you still worried about how to maintain it and maximize the benefits? Today, we will answer all your questions through this article.

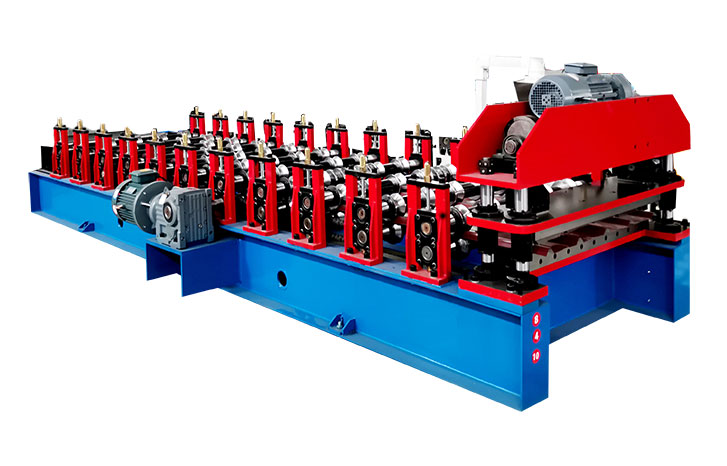

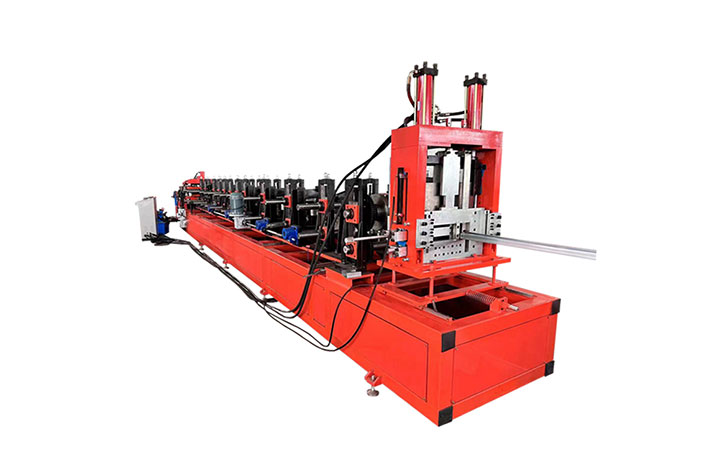

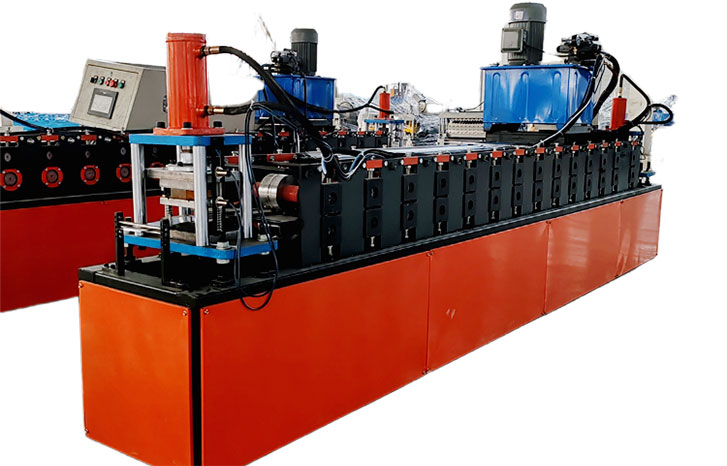

1. What is CZ purlin roll forming machine?

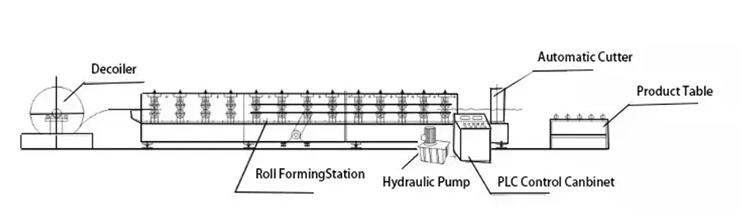

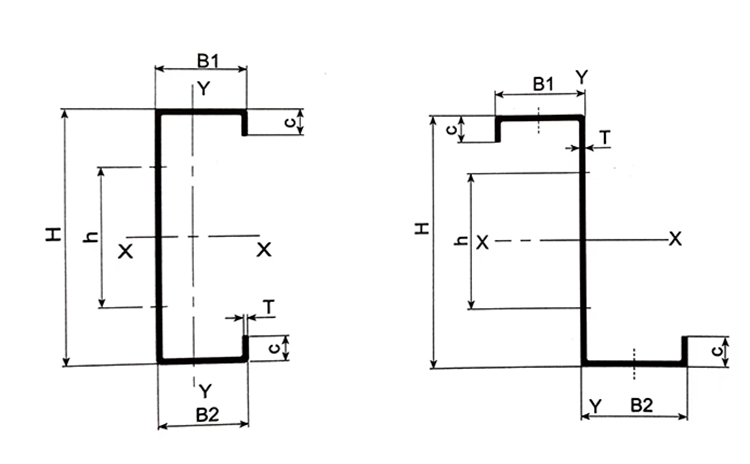

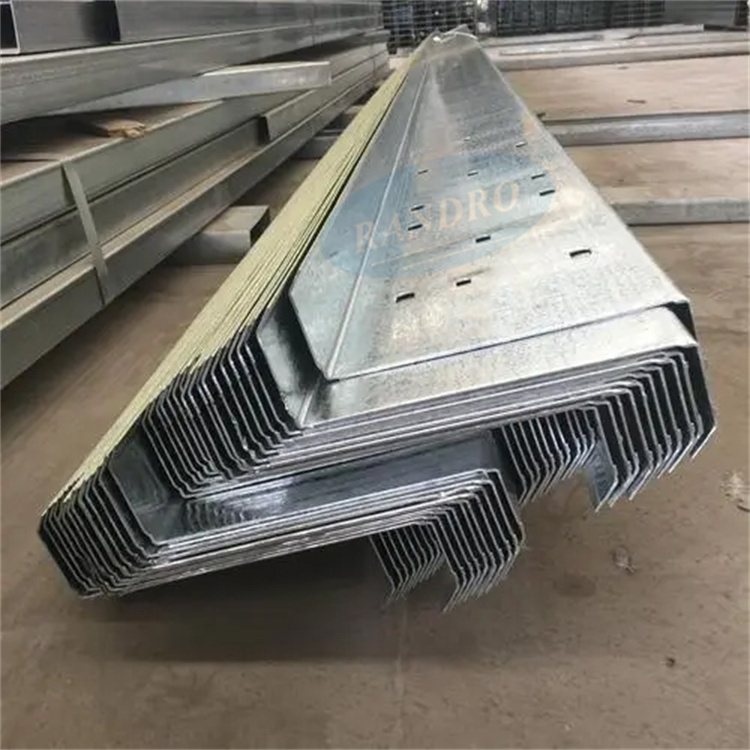

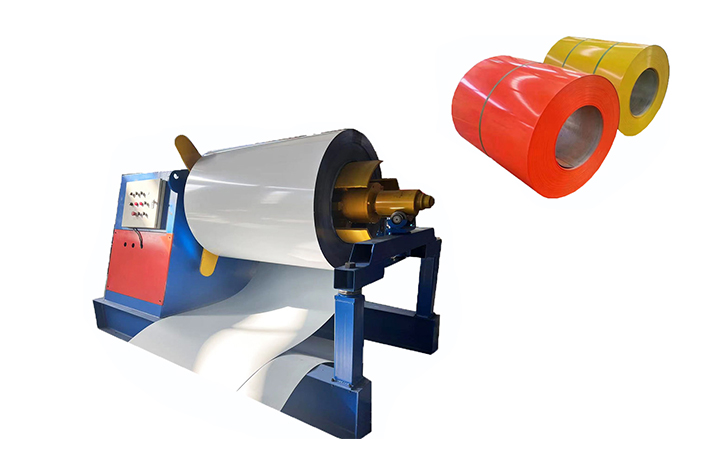

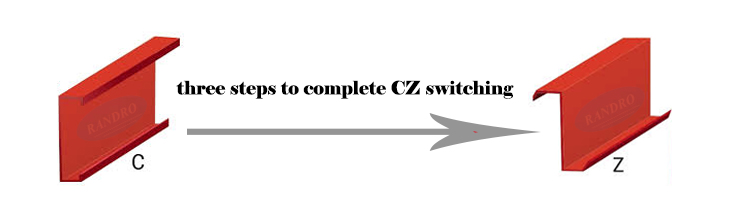

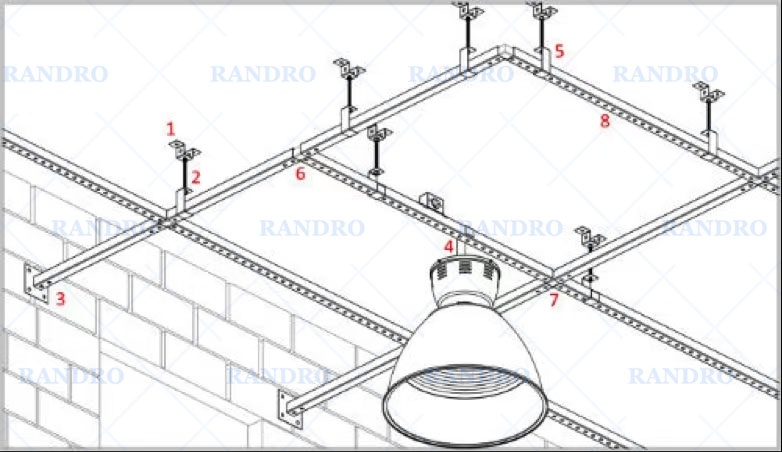

CZ roll forming machine, also known as C-shaped steel machine or CZ Purlin Machine, is a kind of equipment used to produce C-shaped and Z-shaped cold-bent steel. The fully automatic CZ forming machine has multiple functions, including feeding device, roller assembly, forming and discharging, and PLC control cabinet, etc. Its main technical parameters include rolling applicable plates, rolling speed, forming pass, chassis material, side plate structure, transmission mode, shearing and stamping system, cutting knife material, hydraulic system working pressure, etc. The process flow of CZ steel forming machine has been continuously improved, from the initial manual fixed-length cutting and punching to the current full process automatic control, which greatly improves production efficiency.

|  |

2. How to choose the right CZ roll forming machine model?

First, clarify the specific requirements of the project for C-shaped steel or Z-shaped steel, including size, thickness, material and quantity. Second, according to the project requirements, select a forming machine that meets the technical parameters, such as rolling applicable plates, rolling speed, forming passes, etc. Third, according to the needs, consider the automation level of the forming machine, such as automatic type change, automatic punching, automatic cutting and other functions. Fourth, choose a supplier that provides comprehensive after-sales service, technical support and training to quickly solve problems in production. Fifth, according to the market research report, understand the development trend and prospects of the industry, and choose equipment models with good market prospects.

3. How to ensure product quality and production efficiency during the production process of CZ forming machine?

First, introduce automation technology, CNC technology and intelligent control system to improve production efficiency and product quality. Second, adjust equipment parameters, optimize operating processes or introduce automation equipment to reduce waiting time and waste. Third, regular maintenance plan, including routine maintenance such as cleaning, lubrication, tightening, and regular replacement of wearing parts. Strengthen employee training on equipment operation skills. Fourth, provide customized equipment, integrate many processes required for production, such as automatic material changer, cutting and stamping system, to improve production capacity. Fifth, use high-quality roller materials and spindle materials, use heat treatment and precision processing to ensure the durability and stability of the equipment.

|  |

4. How to maintain CZ purlin roll forming machine?

First, regularly clean the dust and debris on the surface of the equipment, especially the key components and moving parts. Second, regularly check whether the fastening parts such as bolts and nuts are loose, and tighten them in time. Third, add appropriate lubricating oil to each lubrication point in accordance with regulations to ensure good lubrication and reduce wear. Fourth, observe the tension and wear condition of transmission parts such as chains and belts, and adjust or replace them in time. Fifth, check whether the wires, plugs, etc. are intact, and whether there are any damage or poor contact. Sixth, ensure that the operator is familiar with the operating procedures and maintenance requirements of the equipment to avoid equipment damage due to improper operation. Seventh, if the equipment is shut down for a long time, take protective measures, such as covering the dust cover.

|  |

If you need a CZ purlin roll forming machine, please contact us. We will provide you with the best quality machine. If you have other machine requirements, such as U-type, T-type, Omega type, etc., please contact us and we will provide you with a customized solution based on your needs.

2024-08-24 22:19:08

2024-08-24 22:19:08

Contact us for detail

Contact us for detail