Brief Introduction

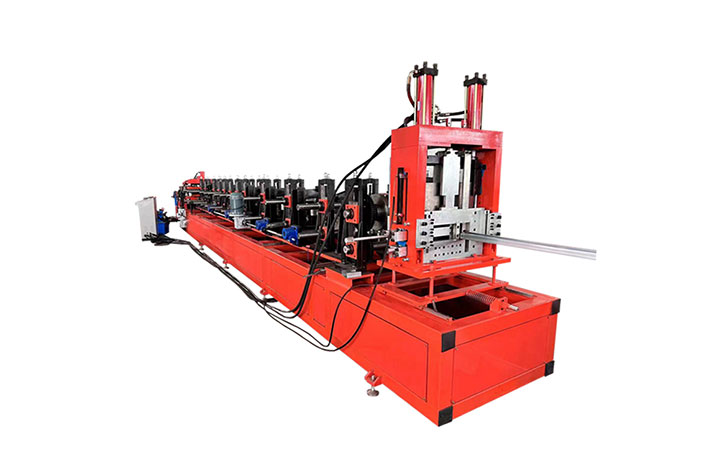

The anode plate cold roll forming machine is controlled by PLC and is used to produce various types of anode plates. The entire anode plate roll forming machine production line including the punching device, with good hole position accuracy and easy and quick installation.

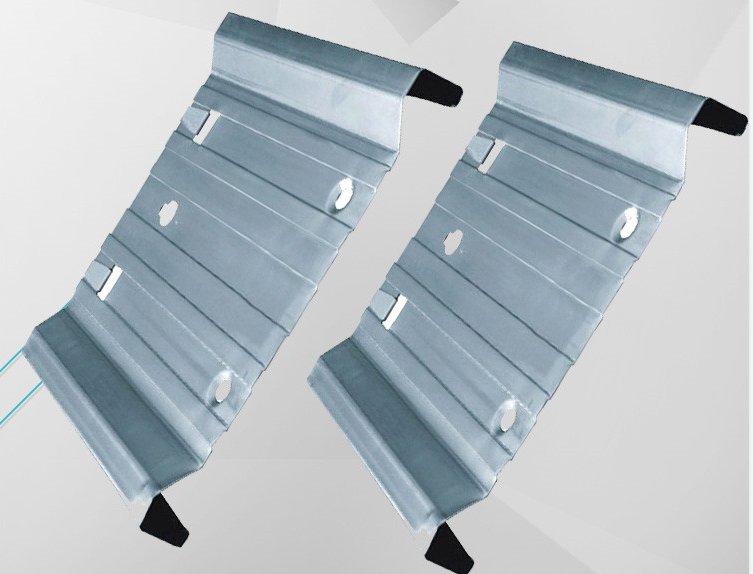

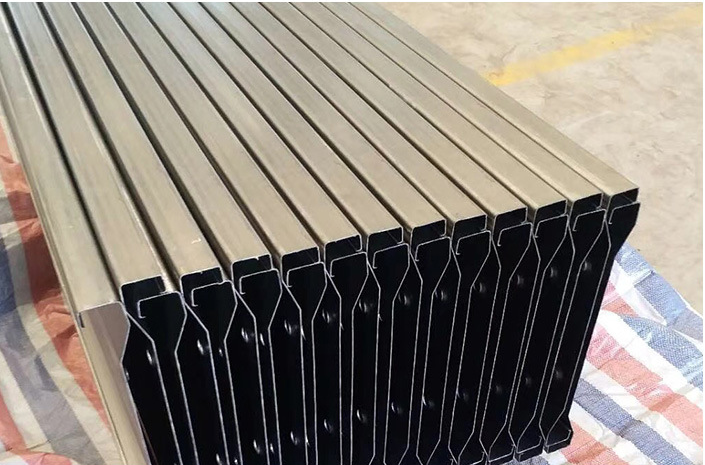

Customized Anode Plate

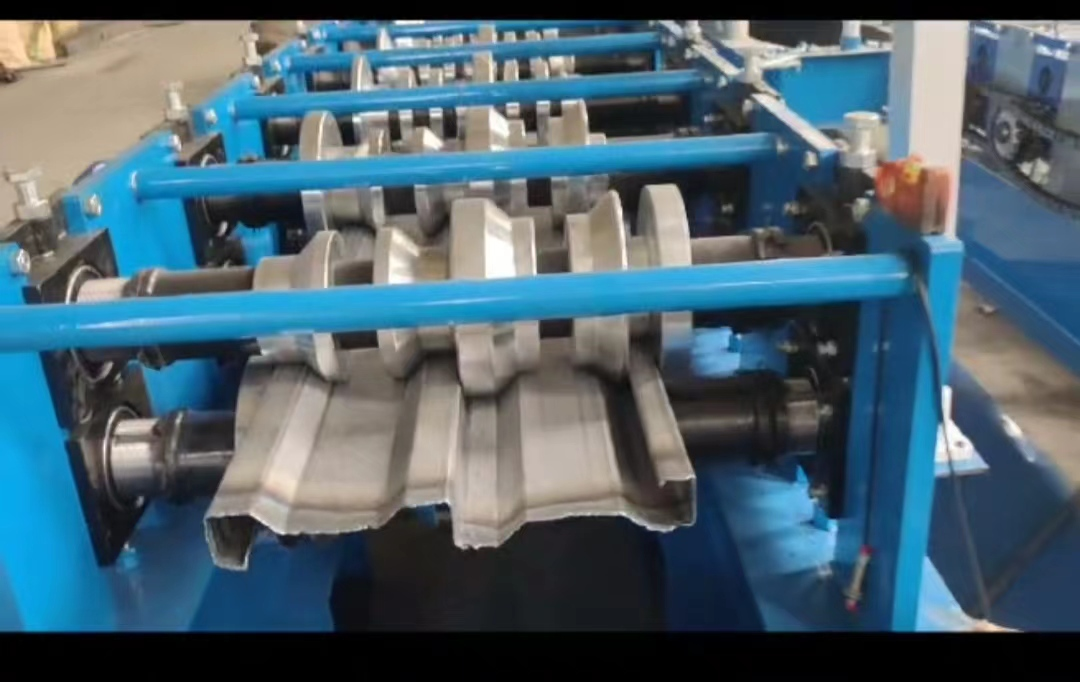

Anode plate roll forming process

Automatic feeding - guiding - leveling, feeding - continuous punching - forming - lengthening, cutting - receiving table

Anode plate forming machine parameters

Material specifications | Q235 galvanized carbon steel |

Material thickness | 2.5-3MM |

Working speed | 4000/working day |

Cutting size tolerance | ≤ ±0.5mm(Length≤3000mm) |

Total motor power | 18KW |

Hydraulic system power | 15KW |

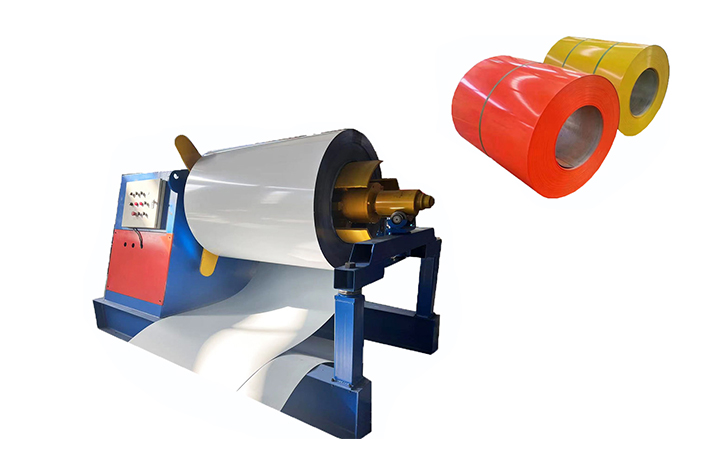

Load-bearing steel belt | 3T |

Number of main rolls | 16-18 |

Cutting method | Hydraulic cutting |

Voltage parameters | 380, 50Hz, 3 phases |

Hydraulic oil model | 46# hydraulic oil |

Gear oil model | 18# double chain gear oil |

Air source | 0.5m3/Min; pressure 0.7MPa |

Main Material for main parts the roll forming machine of the Anode Plate

Roll material | GCr15 Quenched HRC58°-62° |

Drive motor | Variable frequency motor drive |

Cutting mold material | Cr12MoV |

Steel strip width | ≤120 mm |

Steel strip thickness | 2.5-3MM |

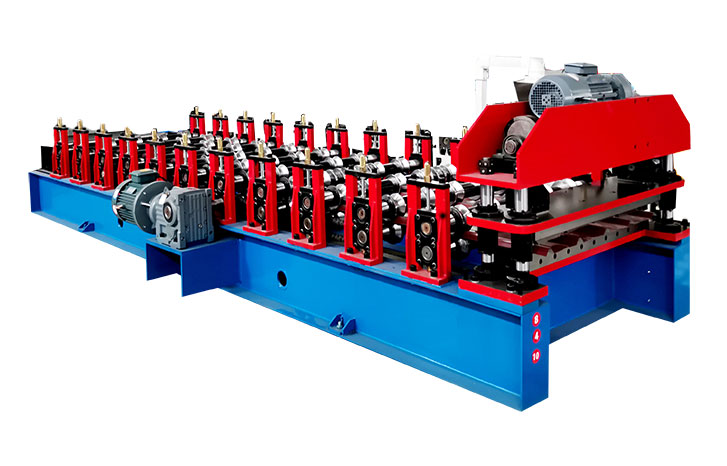

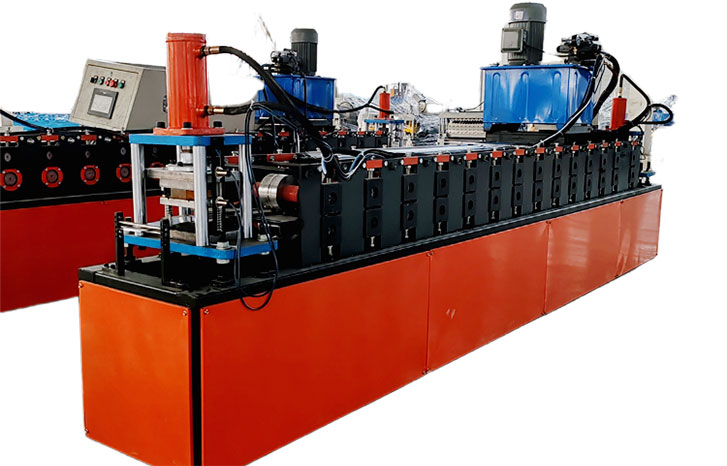

Anode plate cold roll forming machine composition

Anode plate cold roll forming machine includes hydraulic uncoiling, leveling, feeding, punching, forming, shearing and discharging. The control adopts Siemens PLC, anode plate production line, and touch screen input. It has a high degree of automation, easy operation, and high production efficiency. The entire line production speed can reach 40m/min.

2024-03-24 15:48:32

2024-03-24 15:48:32

Contact us for detail

Contact us for detail