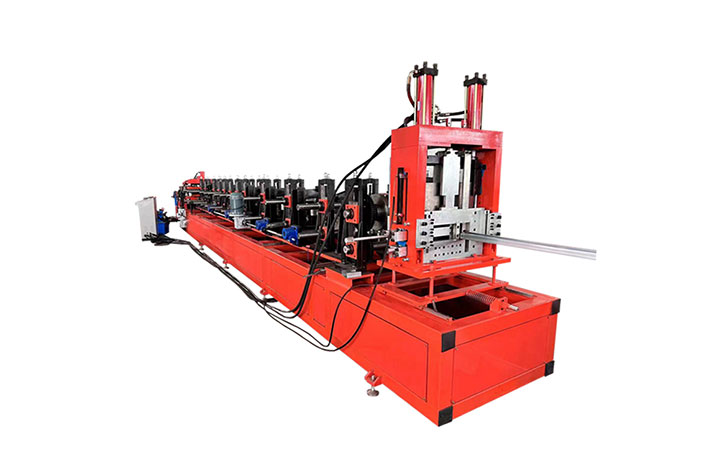

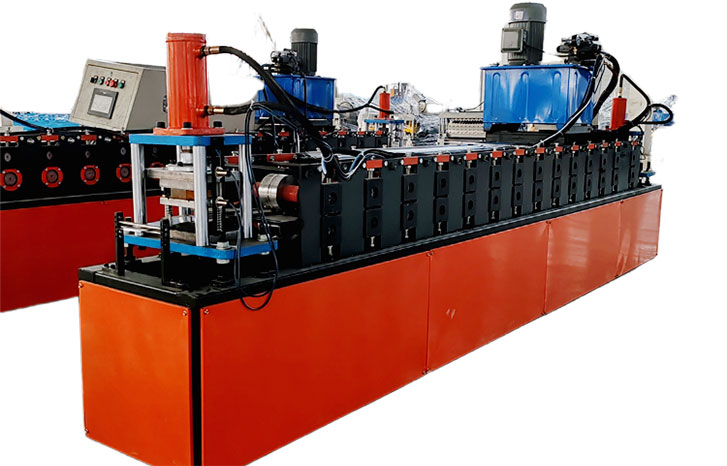

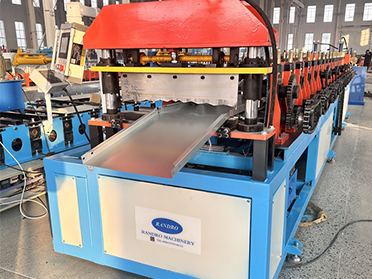

In the rapidly evolving field of electrical installations, cable trays have become an essential component for organizing and supporting various cables. Cable tray making machines play a crucial role in manufacturing these trays efficiently. However, to ensure optimal performance and safety, operators must pay close attention to several key issues when operating these machines. Let's delve into the important considerations that should be kept in mind.

Machine Safety Precautions:

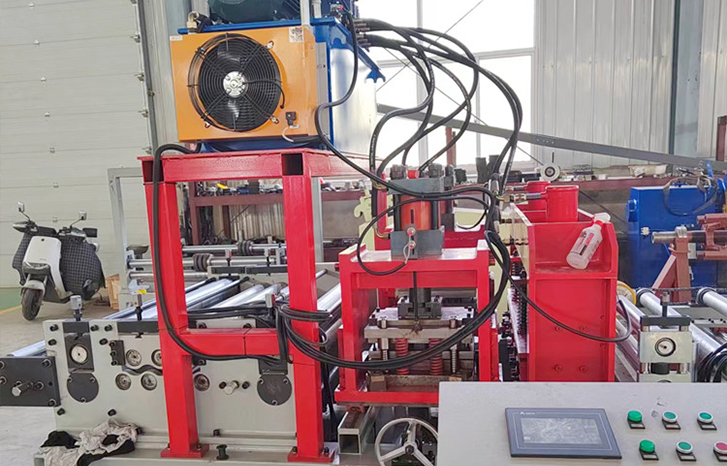

Operating a cable tray making machine requires strict adherence to safety protocols. Operators must familiarize themselves with the machine's safety features, such as emergency stop buttons, safety guards, and interlocking mechanisms. Regular maintenance and inspections should be conducted to ensure the machine is in good working condition, reducing the risk of accidents.

Operator Training:

Proper training is paramount before operating a cable tray making machine. Operators should receive comprehensive instruction on how to operate the machine safely and efficiently. They should be trained to recognize potential hazards, understand the machine's controls, and be aware of emergency procedures. Ongoing training and refresher courses are also essential to stay updated with the latest practices and techniques.

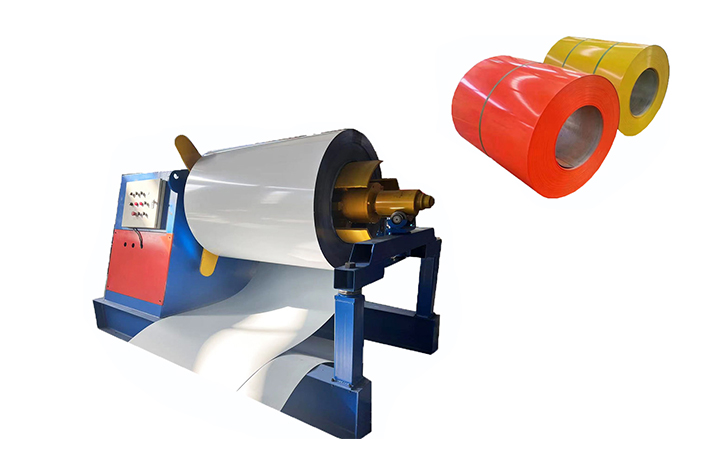

Material Selection:

Choosing the appropriate materials for cable tray production is crucial. The machine's specifications and capabilities should align with the materials being used. Factors such as the tray's load-bearing capacity, corrosion resistance, and electrical conductivity should be considered. Operators must ensure that the materials are compatible with the machine to avoid damage and maintain the desired product quality.

Quality Control:

Maintaining high-quality standards is vital in cable tray manufacturing. Operators should regularly inspect and monitor the produced trays to ensure they meet the required specifications. This includes checking the tray dimensions, surface finish, and structural integrity. Implementing a quality control process helps identify any defects or deviations early on, allowing for timely adjustments and improvements.

Machine Settings and Parameters:

Optimizing the machine settings and parameters is crucial for efficient operation. Operators should be familiar with adjusting parameters such as speed, pressure, and temperature, based on the tray's material and thickness. Fine-tuning these settings can enhance productivity while maintaining the desired quality and precision.

Lubrication and Maintenance:

Proper lubrication and regular maintenance of the cable tray making machine are essential to ensure its longevity and consistent performance. Operators should follow the manufacturer's guidelines regarding lubrication intervals and use high-quality lubricants. Routine maintenance tasks, such as cleaning, tightening bolts, and inspecting components, should be performed diligently to prevent unexpected breakdowns and optimize machine efficiency.

Waste Management:

Effective waste management is a critical consideration when operating a cable tray making machine. Operators should have a system in place to collect and dispose of waste materials generated during the manufacturing process. This includes scraps, cuttings, and other residual materials. Proper waste management not only promotes a clean and organized workspace but also minimizes the environmental impact of the production process.

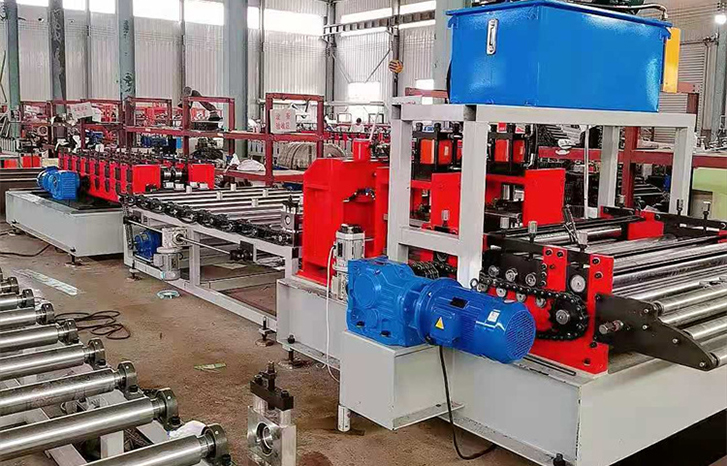

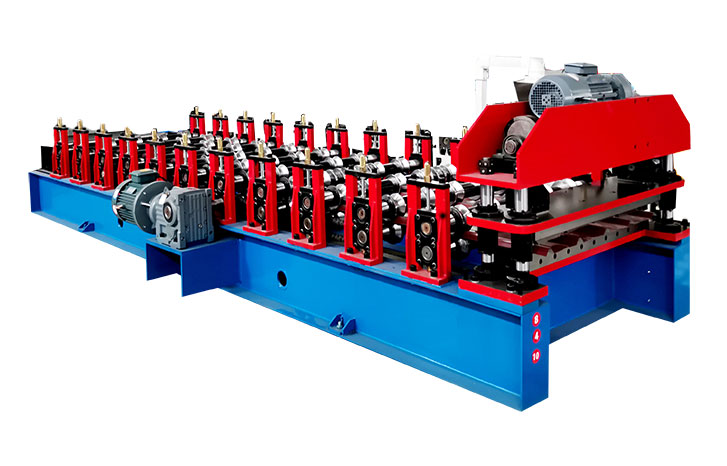

randro has the following advantages in the production of cable tray making machines: firstly, Hengna has rich experience and professional knowledge, and has been committed to the research and development and production of cable tray making machines for many years. Its product line is complete, covering various specifications and types of cable tray making machines, which can meet the needs of different customers. Secondly, randro's cable tray production machine adopts advanced technology and innovative design, which has high efficiency and accuracy, and can quickly and accurately produce high-quality cable tray products. In addition, randro pays attention to quality control and ensures the performance and reliability of each production machine through strict inspection and testing processes. In addition, randro provides comprehensive after-sales service and support, including training, maintenance, and spare parts supply, to ensure that customers can fully utilize their cable tray making machines and achieve optimal production efficiency. In short, randro has become a leader in the industry in the production of cable tray making machines, relying on its experience, technology, and service advantages.

2024-02-23 14:48:04

2024-02-23 14:48:04

Contact us for detail

Contact us for detail