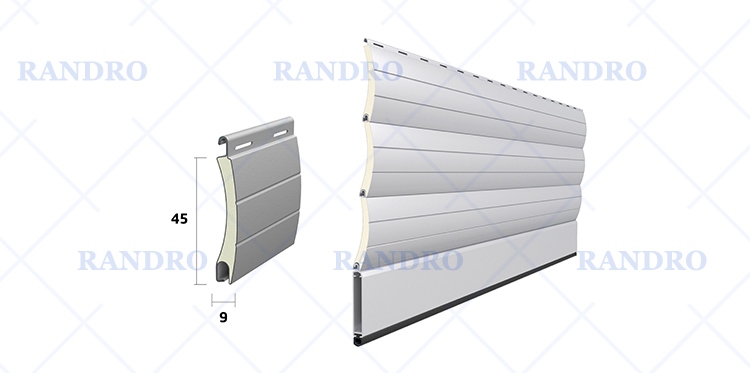

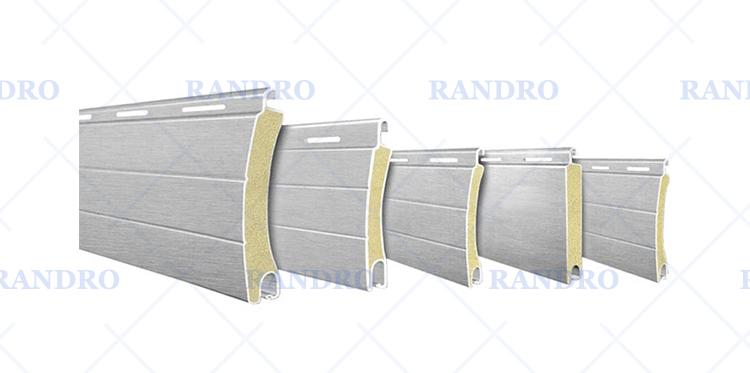

Foamed rolling shutter doors are suitable for various places that require efficient opening and closing, thermal insulation, environmental isolation or fire isolation, such as industrial workshops, logistics storage workshops, large commercial buildings such as supermarkets, shopping centers, etc. At the same time, some special fields, such as cold chain logistics environments, dangerous goods storage areas, special wards in hospitals, etc. are also used.

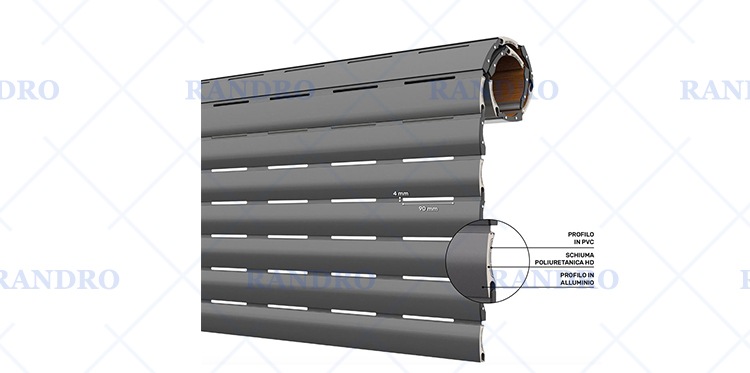

Contact UsFoam rolling shutter doors are a common type of industrial door, usually used for entrances and exits of workshops, warehouses and other places. They are usually made of foam materials, such as polyurethane foam, and have functions such as thermal insulation and fire prevention. The design of this door enables it to be opened and closed quickly, while also effectively isolating the environment and preventing dust, foreign matter, etc. from entering the internal space.

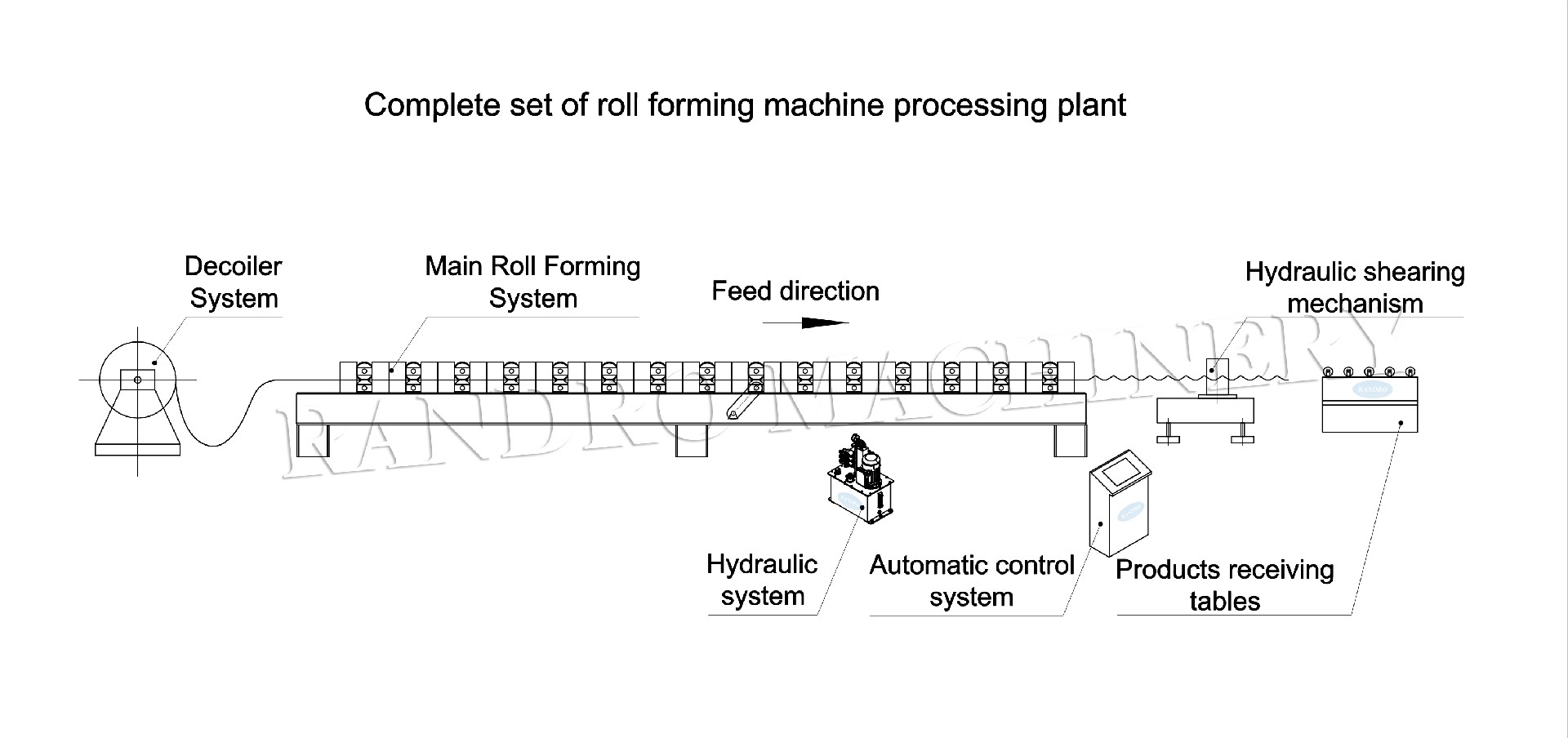

Uncoiler is a mechanical device used for unwinding and unwinding metal coils. It is usually used with punching machines, cold bending forming machines, etc., and is used for unwinding or winding various types of metal coils.

Stracker is a mechanical device used for receiving and stacking formed products. It is usually used with cold bending forming machines and placed at the discharge of the forming machine to complete the stacking and packaging of products.

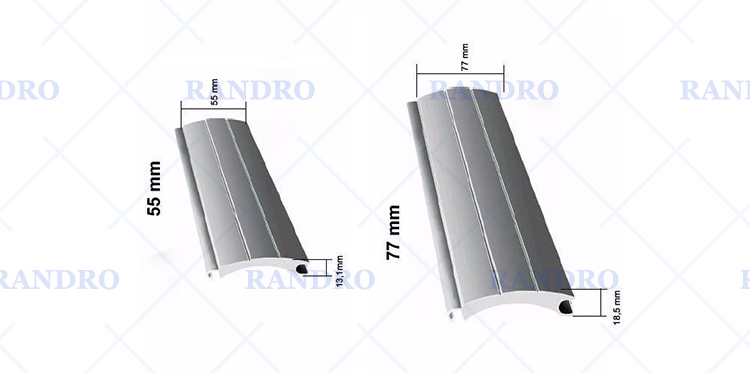

| 1 | Raw Material | Galvanized color steel/aluminum /stainless steel strip |

| 2 | Material thickness | 0.2-0.6 mm or customized |

| 3 | Machine speed | within 20-30m/min |

| 4 | Forming station | 35 stations |

| 5 | Roller material | GCr15 high-quality steel heat treatment (HRC58-62) |

| 6 | Shaft material | No. 45 high-quality steel quenched and tempered (HRB260-280); shaft diameter φ40-50, |

| 7 | Machine base frame | adopt thick-wall steel welding (gantry planing processing) |

| 8 | Machine stands | adopt detachable wall cast iron material structure |

| 9 | Transmission Method | Gearbox Vientiane section transmission |

| 10 | Main motor power | 11KW variable frequency speed regulating motor |

| 11 | cutting motor power | 2.4 kw , flying saw cut type |

| 12 | Cutting off the working state of the flying saw | using pneumatic pressure and return; tracking the flying saw to cut without stopping the machine |

| 13 | Cut off flying saw blade material | original imported alloy saw blade |

| 14 | PU foam pouring machine | single-group low-pressure reaction pouring machine; high-precision internal gear pump, steplessly adjustable discharge volume, |

| heating function, cleaning function | ||

| 15 | Control system | the whole machine adopts industrial panel control (automatic cut-off at fixed length) |

If you are interested in our products, you can leave a message below, and we will reply to you promptly.