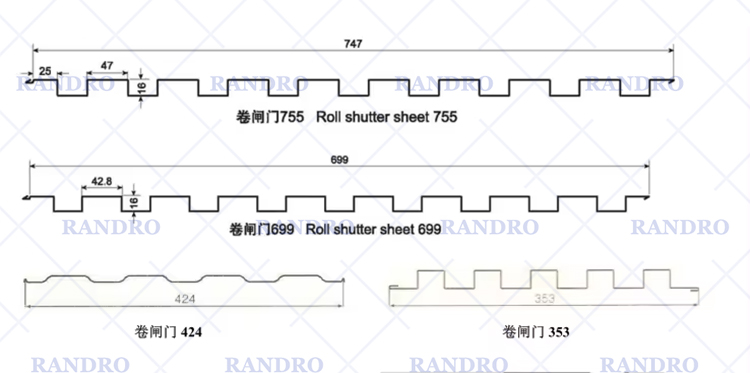

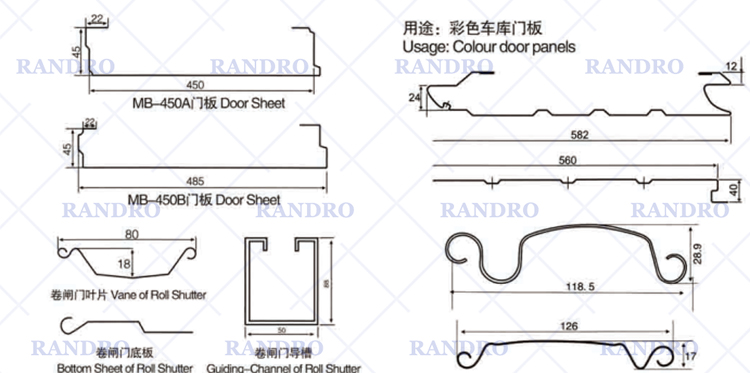

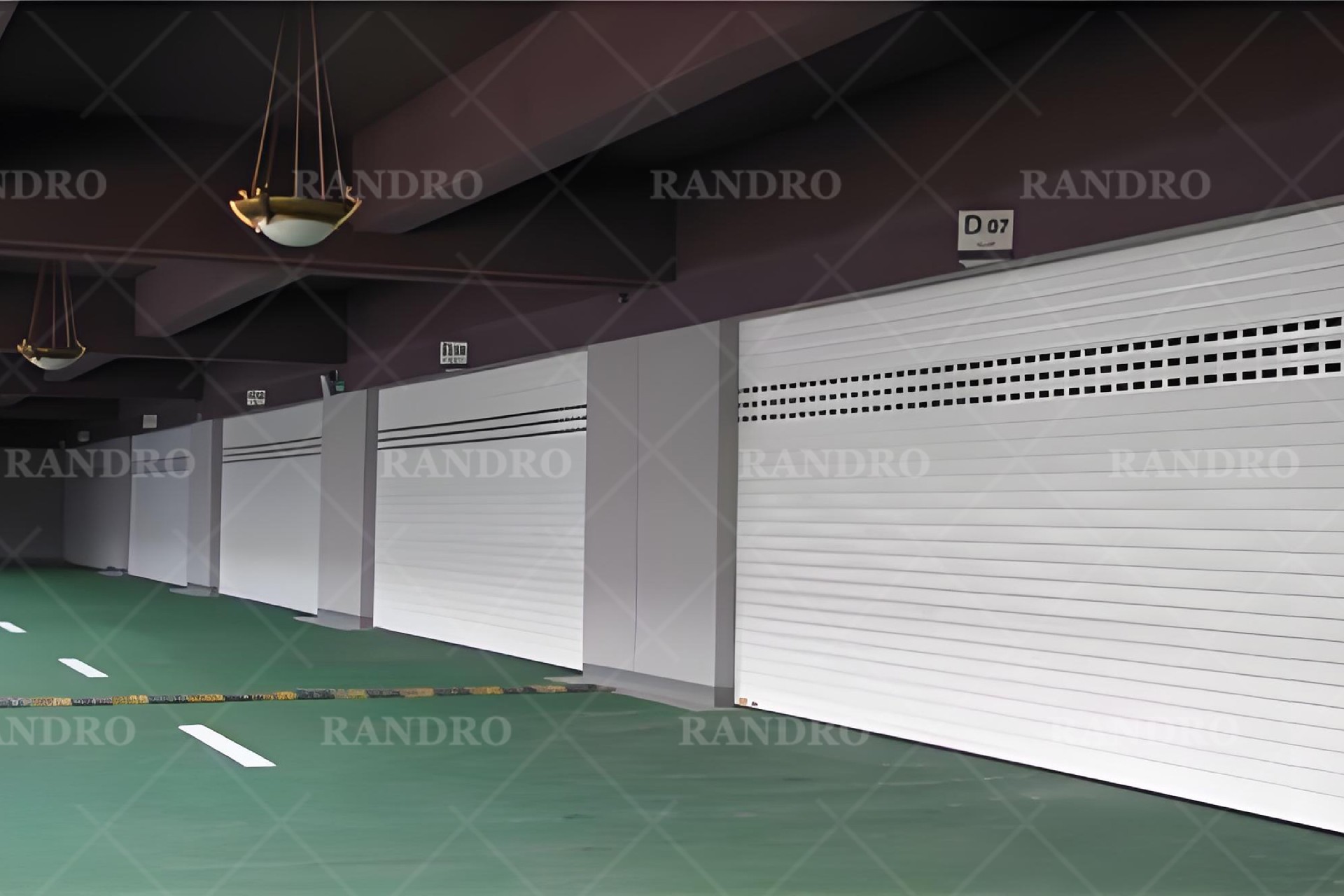

Rolling shutter doors are widely used in various occasions. They are commonly found at the entrances and exits of industrial plants and can improve the safety and work efficiency of the plants. Because of its aesthetics and ease of operation, it is also widely used in commercial buildings such as shopping malls, supermarkets, office buildings and other places. In addition, it is also used as entrances and exits or partitions in private or public garages, stadiums, schools, hospitals and other places. Various rolling shutter doors are common.

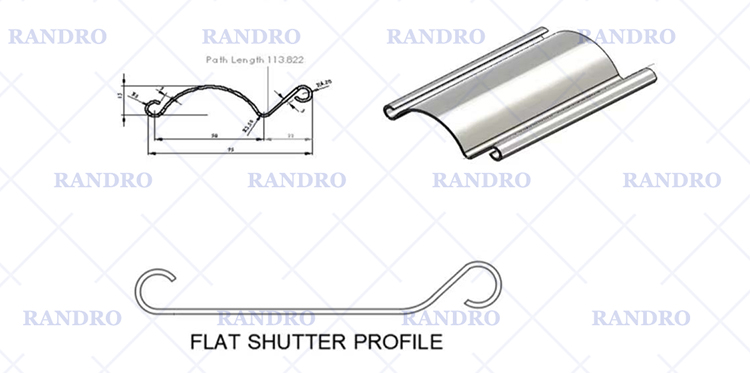

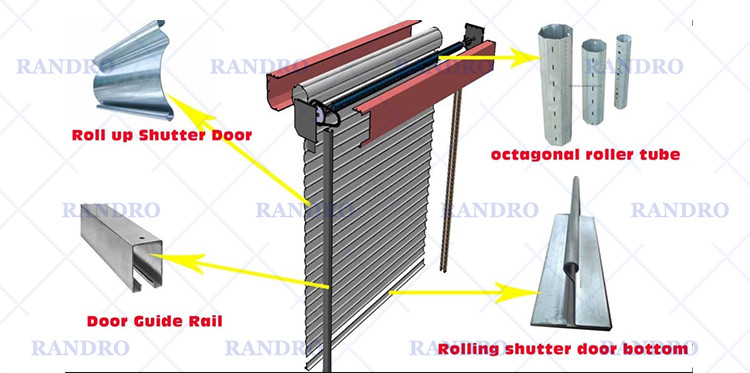

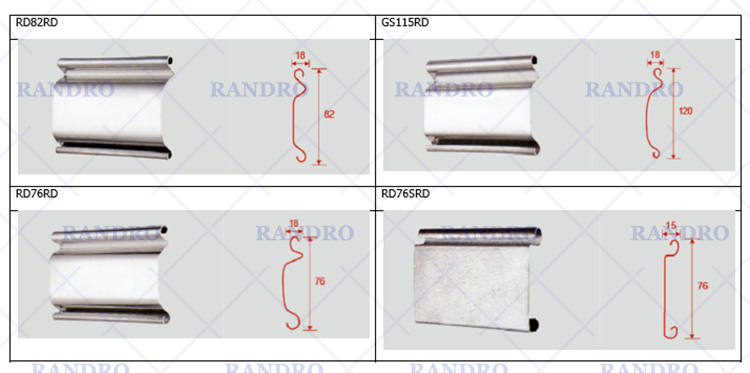

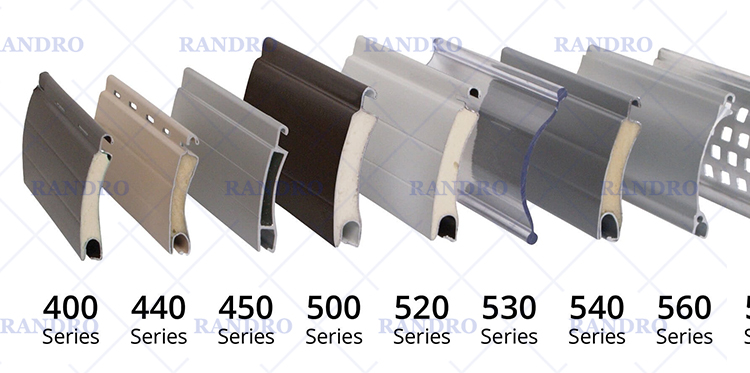

Contact UsRolling shutter door, also known as rolling shutter door, is a door with multi-joint movable door pieces connected in series. In a fixed slide, the door rotates up and down with the scroll above the door as the center. They are divided into manual rolling shutter doors and electric rolling shutter doors. This page mainly covers metal rolling shutter doors, aluminum alloy rolling shutter doors, stainless steel rolling shutter doors, color steel plate rolling shutter doors, and reinforced wind-resistant rolling shutter doors.

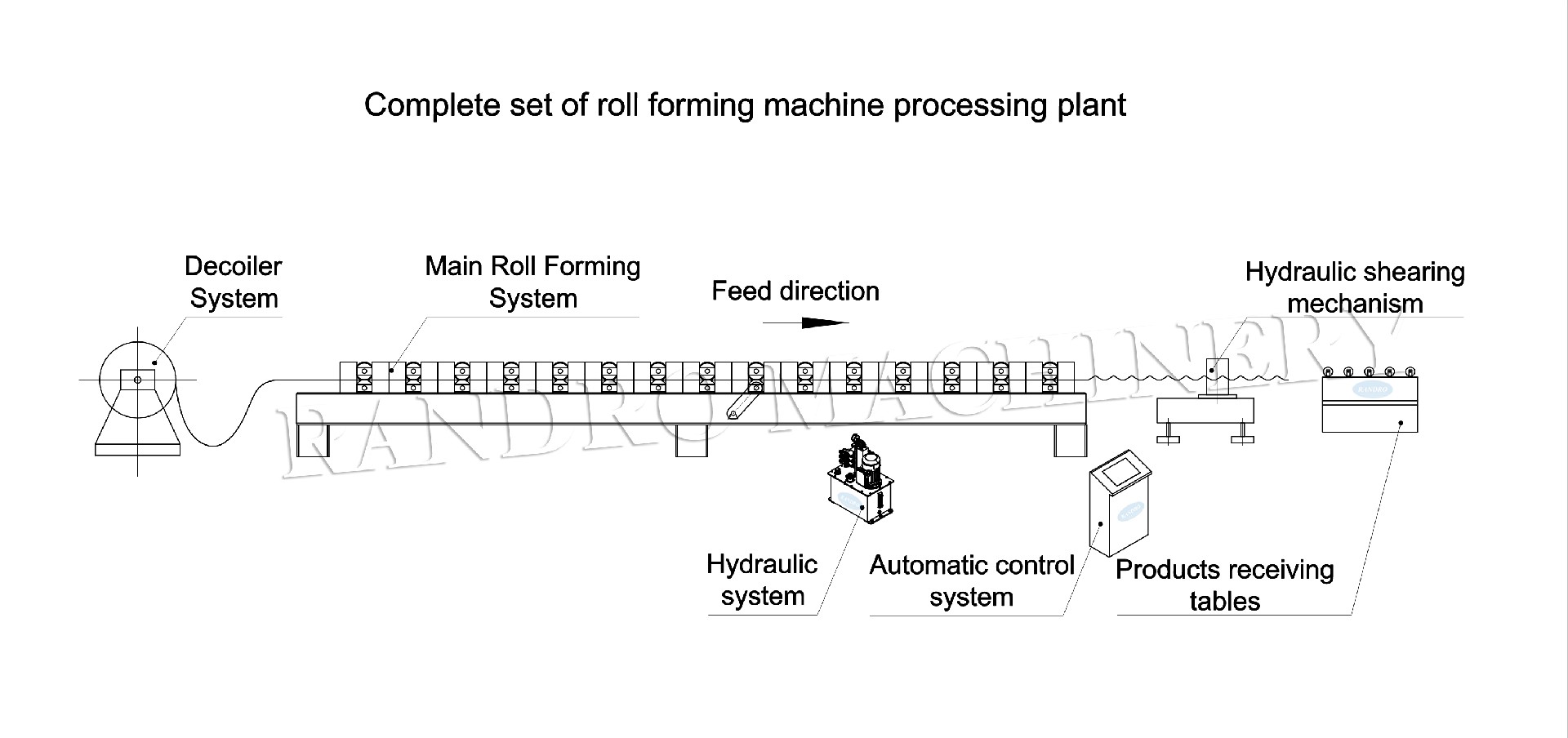

The decoiler is a mechanical equipment used for unwinding and unfolding metal coils. It is divided into manual decoiler, electric decoiler, heavy-duty decoiler, hydraulic decoiler and double-head decoiler. It is usually used with punching machines, cold bending forming machines, etc., for unwinding or rewinding various types of metal coils, and is often used in the metal processing and manufacturing industries.

The stacker is a mechanical equipment used for receiving and stacking molded products. There are simple receiving table, as well as auto stacker for palletizing roof panels and purlin, It is usually used with a cold bending forming machine and placed at the discharging point of the forming machine to complete the stacking and packaging of products. It is often used in the metal processing and manufacturing industries.

| No. | Type | Specification | |

| 1 | Row Material | Type | Colored steel plate, Galvanized board, Aluminum plate ect |

| Feeding width | 122mm or According to client’s requirement | ||

| Thickness | 0.7-0.8mm | ||

| 2 | Main Body | Forming roller station | 12 Stations |

| Diameter of shaft | 40mm | ||

| Shaft material | High grade 45# steel | ||

| Roller material | High grade 45# steel , hard treatment and polishing ( plated chrome on surface ) | ||

| Frame thickenss | 14 mm | ||

| Working speed | 8-15 m/min | ||

| Size(L*W*H) | About 6800*850*1310mm | ||

| Weight | About 2.5 tons | ||

| Motor power | 3 kw | ||

| Hydraulic power | 3 kw | ||

| Voltage | 380V 50Hz 3phases or Customerization | ||

| 3 | Power | Drving Way | By Gear |

| Language | English and Chinese | ||

| Brand Of PLC | Delta brand ( Touch Screen ) | ||

| Operation | Manual and Automatic ( Two Type ) | ||

| 4 | PLC Control System | Transducer | Delta brand |

| Cutting Type | Hydraulic Cutting | ||

| 5 | Cutting Device | Blade of Cutting | Cr12 , quenching treatment |

If you are interested in our products, you can leave a message below, and we will reply to you promptly.