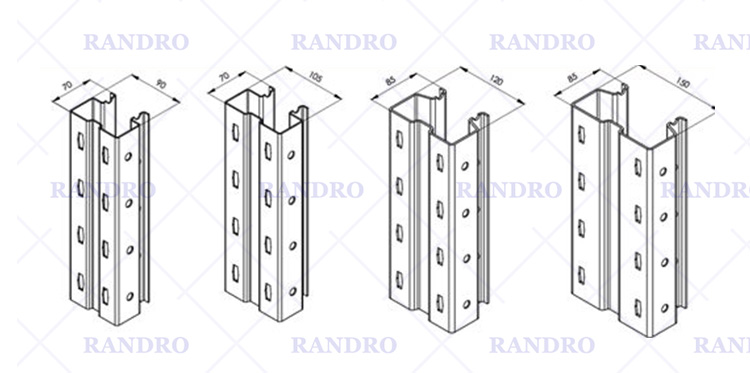

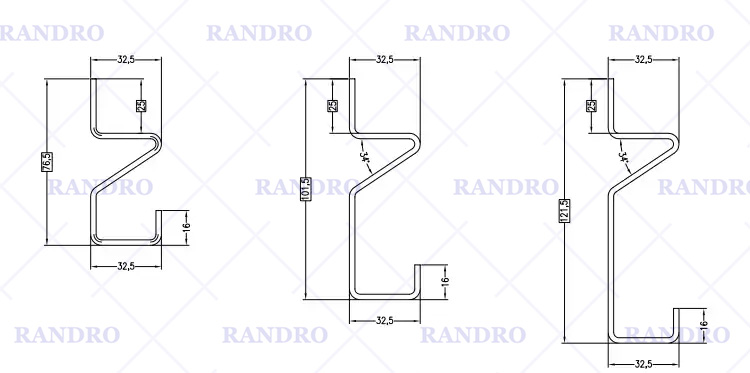

Light punched shelves have strong versatility and are widely used in assembling light material racks, workbenches, tool carts, suspension systems, safety nets and support frames. Medium-sized shelves have unique shapes, are easy to assemble and disassemble, and have large carrying capacity. They are widely used in shopping malls, supermarkets, corporate warehouses and institutions. Heavy-duty shelves are widely used in manufacturing, third-party logistics, and distribution centers.

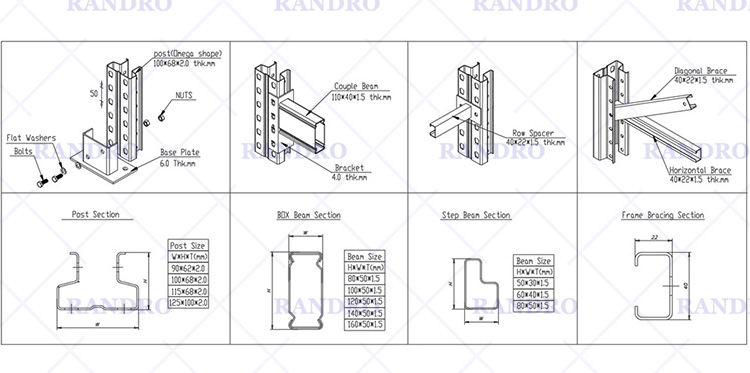

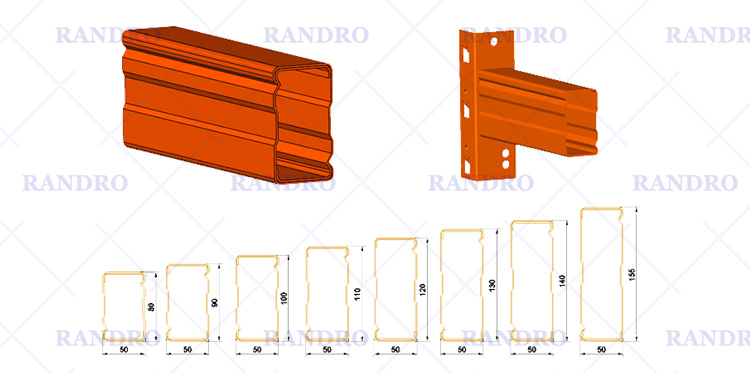

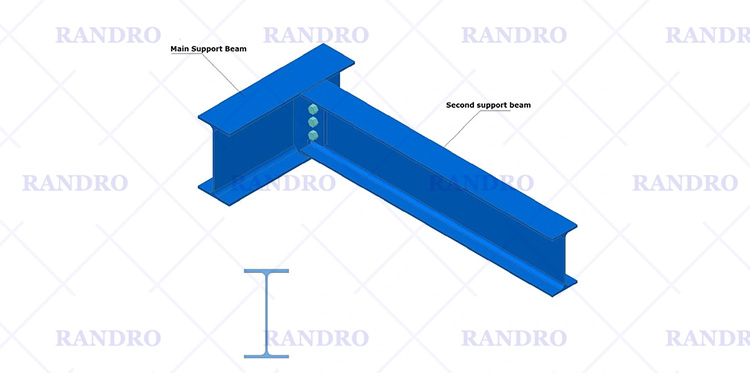

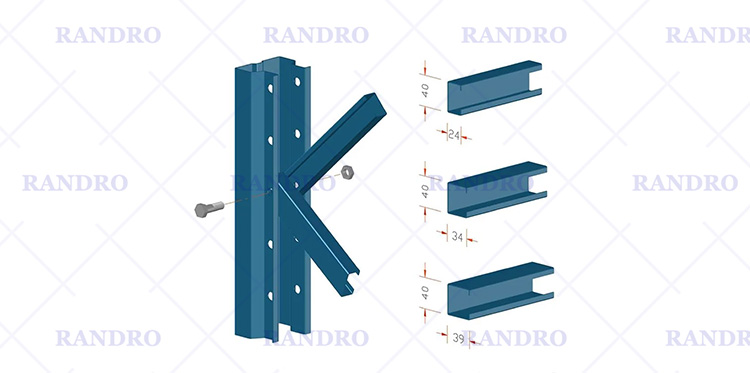

Contact UsShelf forming equipment can produce various storage shelves. It is one of the main facilities of warehousing and an indispensable component of modern industrial warehouses, logistics centers, and distribution centers. Storage shelves usually have three major accessories. Heavy-duty, medium-sized and light-duty storage shelves commonly use columns, beams and laminates. Super-heavy and loft-type storage shelves use columns and beams as accessories.

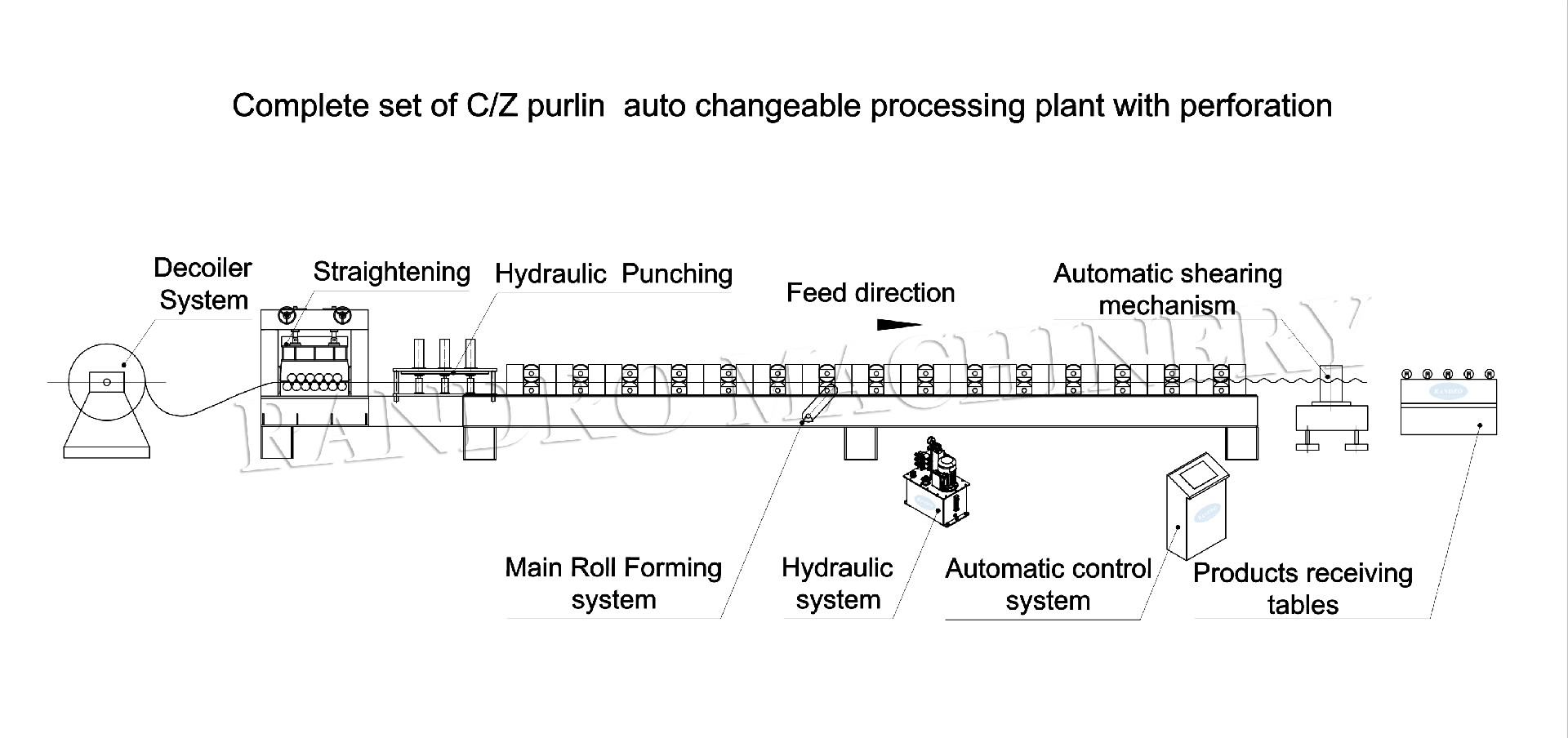

The decoiler is a mechanical equipment used for unwinding and unfolding metal coils. It is divided into manual decoiler, electric decoiler, heavy-duty decoiler, hydraulic decoiler and double-head decoiler. It is usually used with punching machines, cold bending forming machines, etc., for unwinding or rewinding various types of metal coils, and is often used in the metal processing and manufacturing industries.

The stacker is a mechanical equipment used for receiving and stacking molded products. There are simple receiving table, as well as auto stacker for palletizing roof panels and purlin, It is usually used with a cold bending forming machine and placed at the discharging point of the forming machine to complete the stacking and packaging of products. It is often used in the metal processing and manufacturing industries.

| Item | Type | Main Parameter |

| Formed Material | PPGI,GI | Thickness:2 to 3mm |

| Decoiler | Automatic decoiler | Manual decoiler(will give you as free) |

| Main body | Roller station | 20 rows(As your requirement) |

| Diameter of shaft | 80mm solid shaft | |

| Material of rollers | Gcr12mov | |

| Machine body frame | 500 H steel | |

| Drive | Chain transmission | |

| Dimension(L*W*H) | 9500*1600*1600(customize) | |

| Weight | 6T | |

| Cutter | Automatic | cr12mov material, no scratches, no deformation |

| Power | Motor Power | 7.5KW |

| Hydraulic system | 7.5KW | |

| Voltage | 380V 50Hz 3Phase | As your requirement |

| Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| Forming Speed | 15-20m/min | The speed depends on the shape of the tile and the thickness of the material. |

If you are interested in our products, you can leave a message below, and we will reply to you promptly.