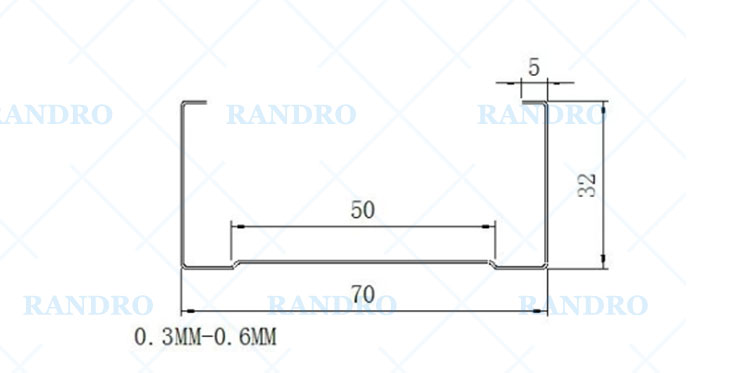

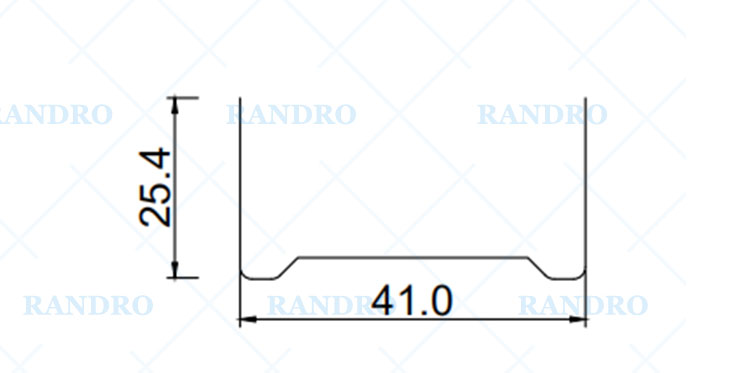

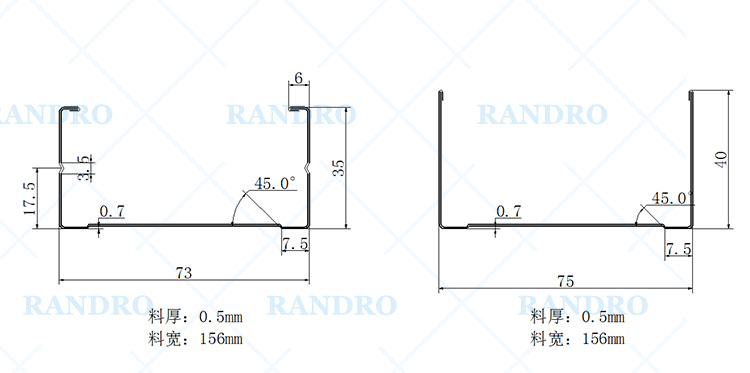

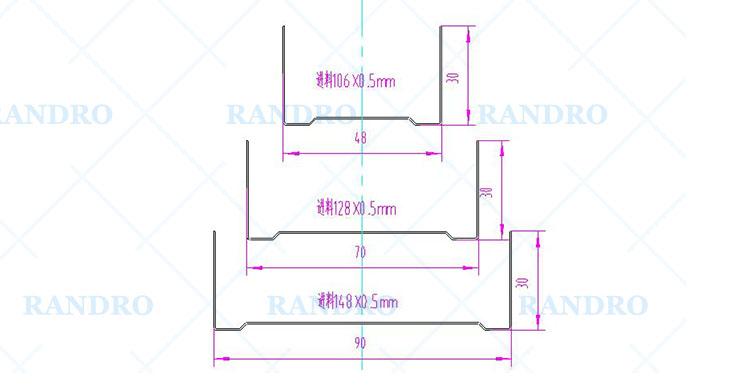

CU keels are mainly used for decoration and renovation. U-shaped keels are mostly used for ceiling keels, main keels, auxiliary keels, and hanging rod hangers. They can also be used as partition keels, such as the top guide beam, bottom guide beam, and vertical columns of composite partition walls. C-shaped keels are mainly used for the construction of light steel villa main materials and are relatively widely used in the field of house construction.

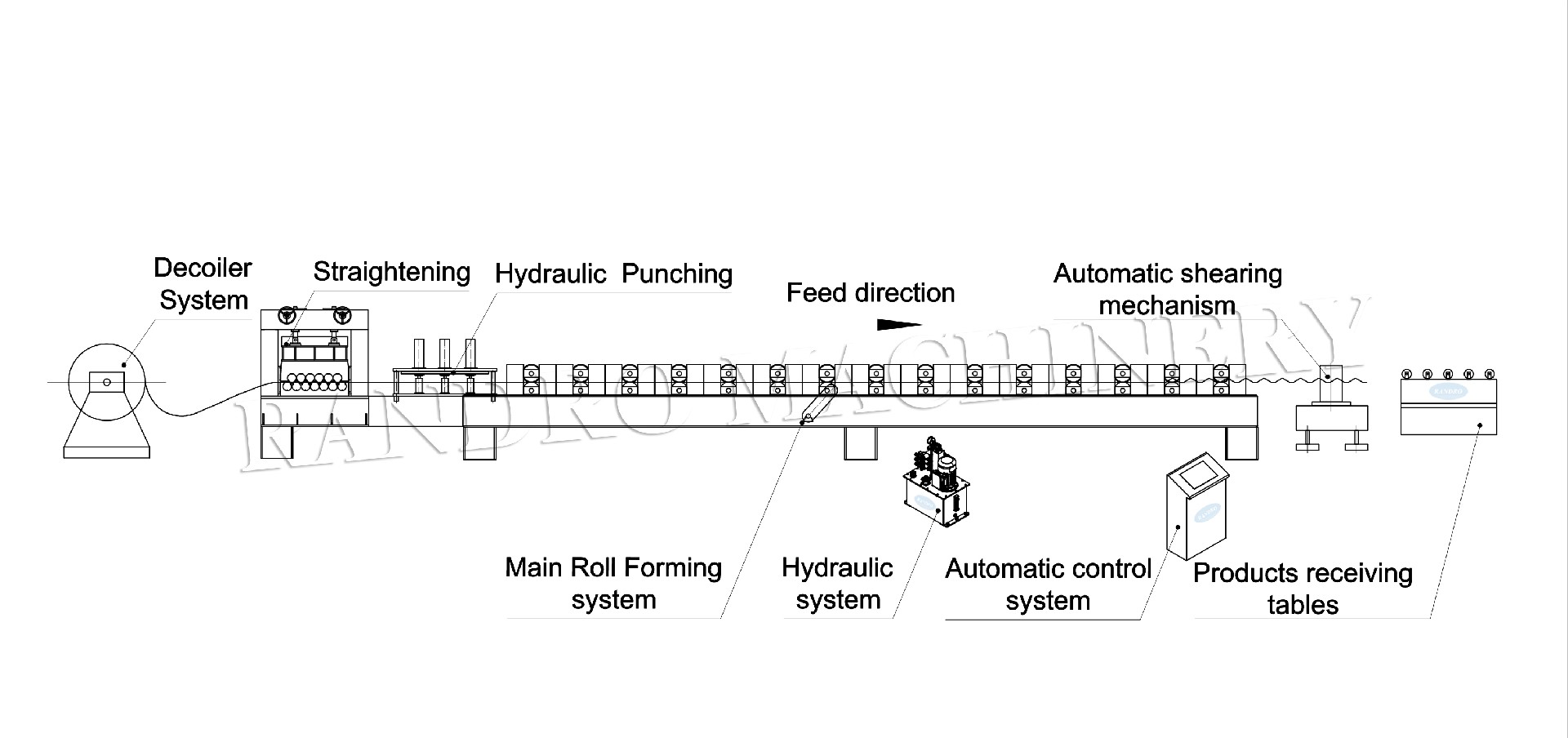

Contact UsCU purlin forming machine is used to produce "C-shaped and U-shaped" cold-bent steel equipment in the steel structure industry. The finished product produced by the machine is CU-shaped steel (purlin), which is mostly used for supporting beams and wall beams in house construction and factory buildings.

The decoiler is a mechanical equipment used for unwinding and unfolding metal coils. It is divided into manual decoiler, electric decoiler, heavy-duty decoiler, hydraulic decoiler and double-head decoiler. It is usually used with punching machines, cold bending forming machines, etc., for unwinding or rewinding various types of metal coils, and is often used in the metal processing and manufacturing industries.

The stacker is a mechanical equipment used for receiving and stacking molded products. There are simple receiving table, as well as auto stacker for palletizing roof panels and purlin, It is usually used with a cold bending forming machine and placed at the discharging point of the forming machine to complete the stacking and packaging of products. It is often used in the metal processing and manufacturing industries.

| Part details | Item Name | Specification |

| 1. Forming material | PPGI, GI, AI, color steel | thickness (0.3 - -1.5 mm) width (customized) |

| 2. Uncoiler | Hydraulic automatic uncoiler (optional) | Manual uncoiler (random gift) |

| 3. Main forming machine | Number of shafts | 10-20 rows (depending on the situation) |

| Bearing diameter | 50mm solid shaft | |

| Roller material | 45# steel, high temperature quenching and chrome plating | |

| Machine body | 350H steel | |

| Drive chain | 2 feet (according to your needs) | |

| 4. Cutter | Fully automatic | cr12mov |

| 5. Kinetic energy | Electric energy | 5.5KW |

| Hydraulic energy | 7.5KW | |

| 6. Voltage | 380V 50Hz 3 Phase | Customizable |

| 7. Control system | Electric box | Customizable (famous brand) |

| Language | English (supports multiple languages) | |

| PLC | complete machine for automated production | |

| 8. Forming speed | 0-40m/min | The speed depends on the shape of the tile and the thickness of the material. |

If you are interested in our products, you can leave a message below, and we will reply to you promptly.