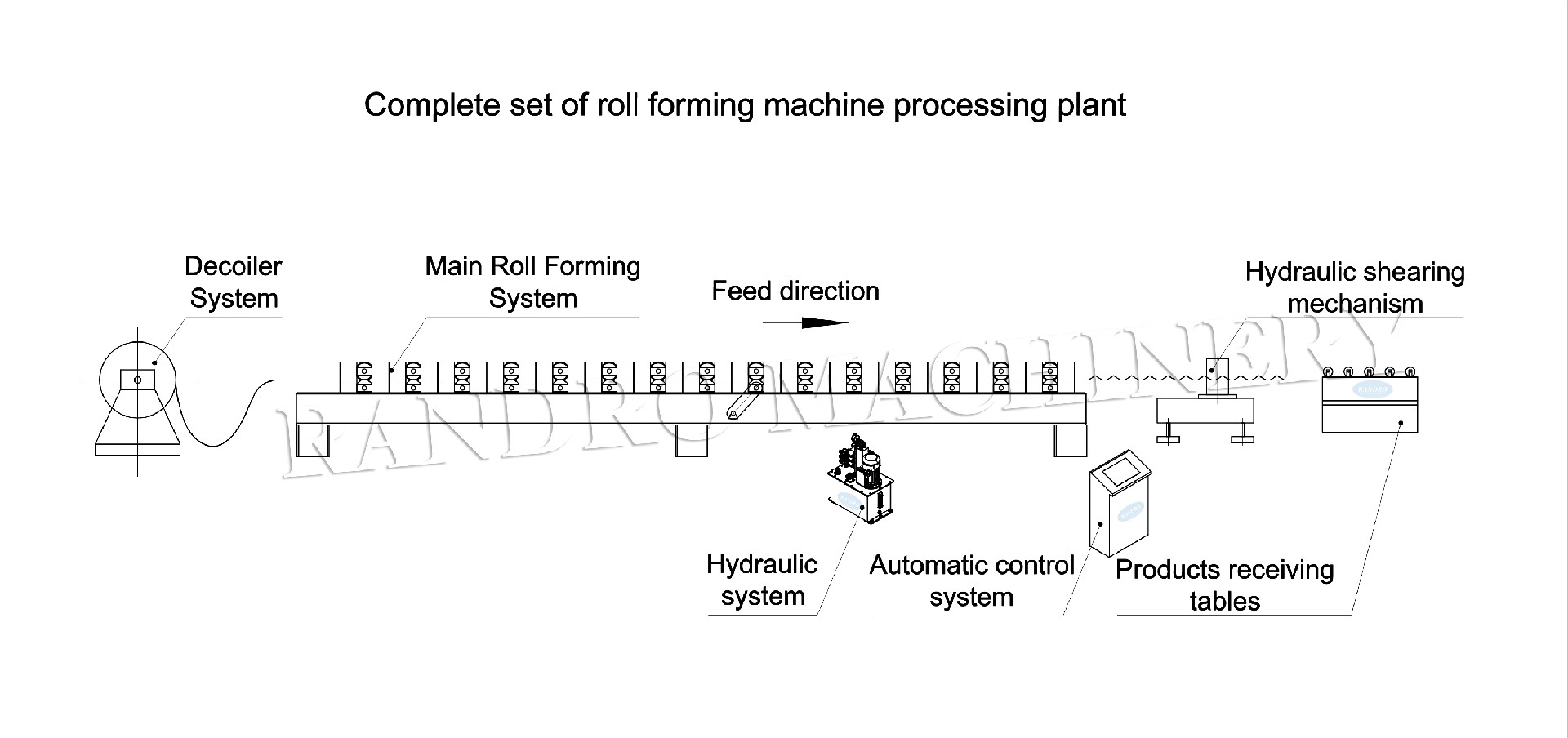

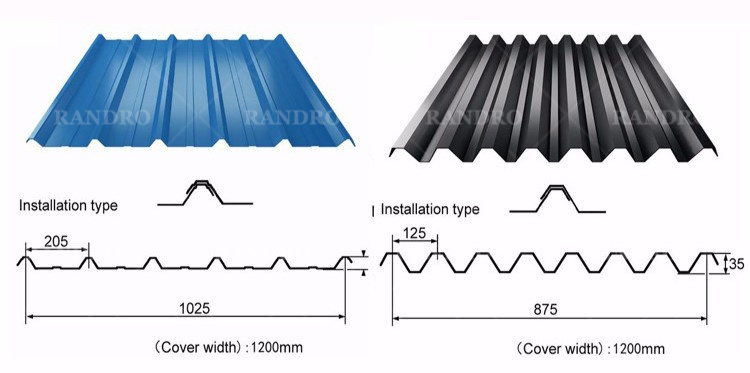

Roll forming machines are mainly used to produce various types of corrugated tiles, roof panels, wall panels and other building materials, and are widely used in the construction industry. Specifically, it is used to manufacture roofs and walls of buildings such as factories, warehouses, shops, farmhouses, greenhouses, car showrooms, stadiums, etc. In addition, the tile press can also produce other types of plates and workpieces, such as metal plates, steel components, etc.

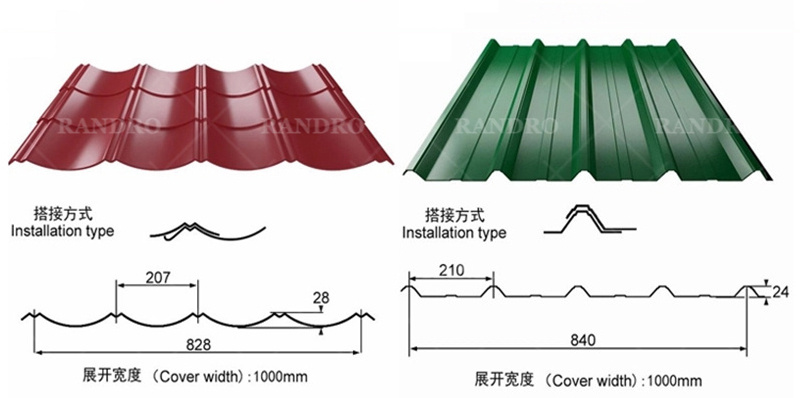

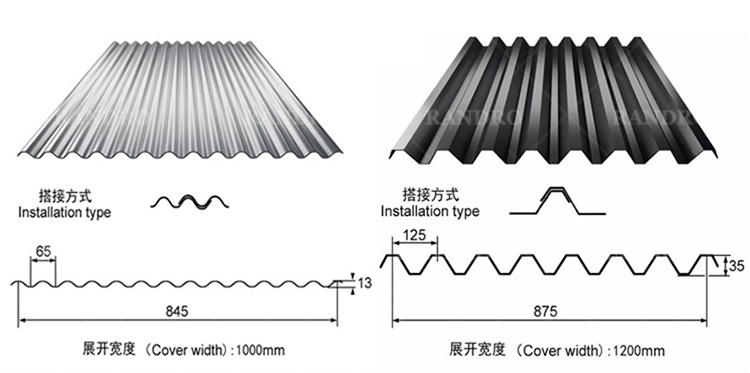

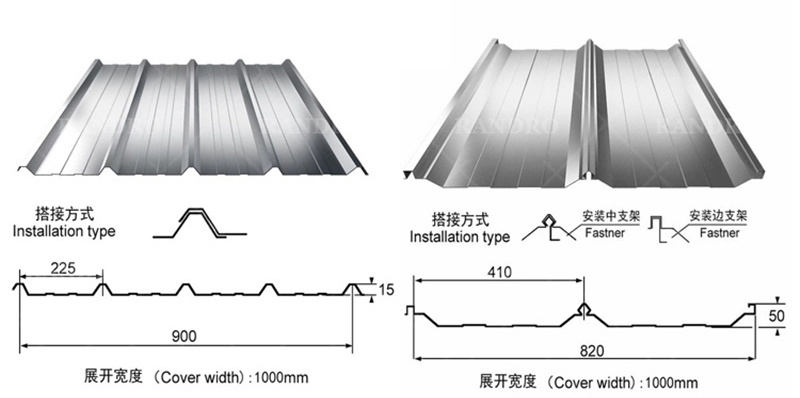

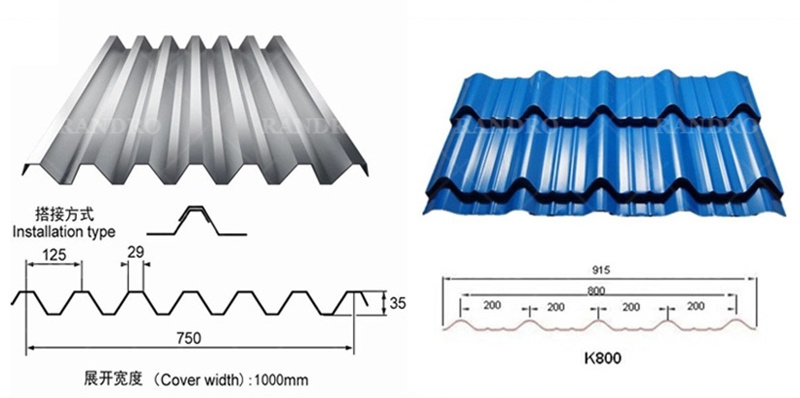

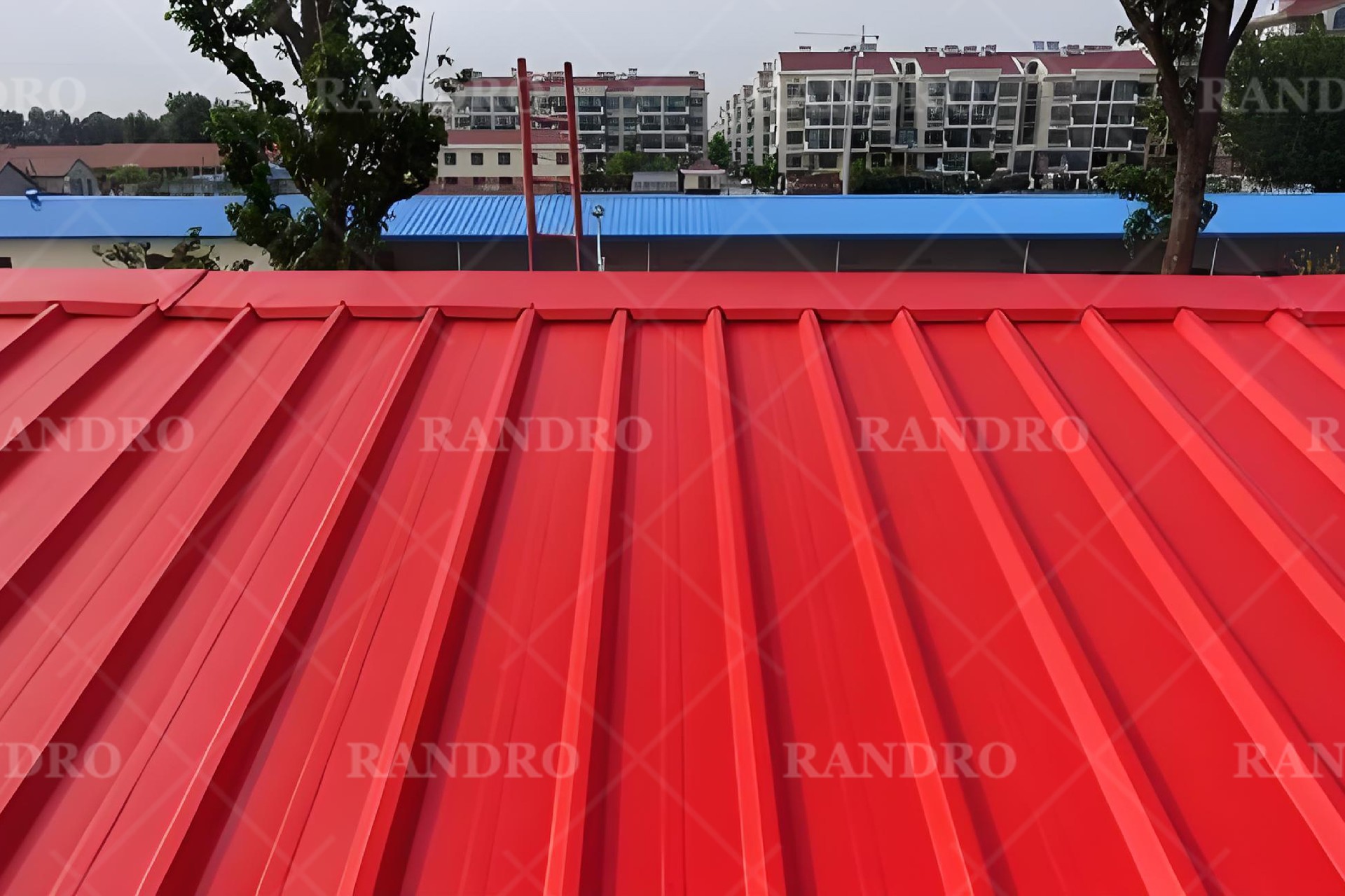

Contact UsThree layers roll forming machine The forming machine is a piece of equipment used to produce metal roof tiles. It is a type of metal roofing tile commonly used in industrial and commercial buildings. Three layers roofing sheet making machine has good pressure resistance and drainage performance. They are commonly used for roof coverings on industrial buildings, commercial buildings and residential buildings, providing excellent weather resistance, corrosion resistance and strength. At the same time, the installation of roofing sheet is relatively simple and can provide a beautiful appearance.

{pboot:if('| No | Item | Specification |

| 1 | Raw Material: | PPGI GI PPGL PPGI Coils |

| 2 | Raw Material Width: | Customized |

| 3 | Effective Width: | Customized |

| 4 | Coil Thickness: | 0.3-0.8mm(can be customized) |

| 5 | Forming Speed: | 10-20m/min |

| 6 | Diameter of Forming Shafts: | 70mm |

| 7 | Main Motor Power: | 7.5kw |

| 8 | Hydraulic Pump Power: | 4.5kw |

| 9 | Rollers Material: | No.45 steel, coated with chromed treatment |

| 10 | Cutter Material: | Cr12 mould steel, with quenched treatment |

| 11 | Control System: | Delta PLC and Converter |

| 12 | Electric voltage: | According to customer’s requirement |

| No | Item | Specification |

| 1 | Raw Material: | PPGI GI PPGL PPGI Coils |

| 2 | Raw Material Width: | Customized |

| 3 | Effective Width: | Customized |

| 4 | Coil Thickness: | 0.3-0.8mm(can be customized) |

| 5 | Forming Speed: | 10-20m/min |

| 6 | Diameter of Forming Shafts: | 70mm |

| 7 | Main Motor Power: | 7.5kw |

| 8 | Hydraulic Pump Power: | 4.5kw |

| 9 | Rollers Material: | No.45 steel, coated with chromed treatment |

| 10 | Cutter Material: | Cr12 mould steel, with quenched treatment |

| 11 | Control System: | Delta PLC and Converter |

| 12 | Electric voltage: | According to customer’s requirement |

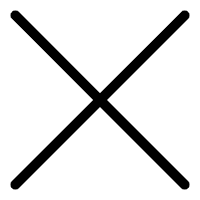

The decoiler is a mechanical equipment used for unwinding and unfolding metal coils. It is divided into manual decoiler, electric decoiler, heavy-duty decoiler, hydraulic decoiler and double-head decoiler. It is usually used with punching machines, cold bending machines, etc., for unwinding or rewinding various types of metal coils, and is often used in the metal processing and manufacturing industries.

Stacker is a mechanical equipment used to receive and stack molded products. There are simple receiving racks and automatic palletizers for roof panels and purlins. It is usually used with a cold bending forming machine and placed at the discharging point of the forming machine to complete the stacking and packaging of products. It is often used in the metal processing and manufacturing industries.

| No | Item | Specification |

| 1 | Raw Material: | PPGI GI PPGL PPGI Coils |

| 2 | Raw Material Width: | Customized |

| 3 | Effective Width: | Customized |

| 4 | Coil Thickness: | 0.3-0.8mm(can be customized) |

| 5 | Forming Speed: | 10-20m/min |

| 6 | Diameter of Forming Shafts: | 70mm |

| 7 | Main Motor Power: | 7.5kw |

| 8 | Hydraulic Pump Power: | 4.5kw |

| 9 | Rollers Material: | No.45 steel, coated with chromed treatment |

| 10 | Cutter Material: | Cr12 mould steel, with quenched treatment |

| 11 | Control System: | Delta PLC and Converter |

| 12 | Electric voltage: | According to customer’s requirement |

If you are interested in our products, you can leave a message below, and we will reply to you promptly.